Our Products

Custom Stand-Up Pouches (Doypacks)

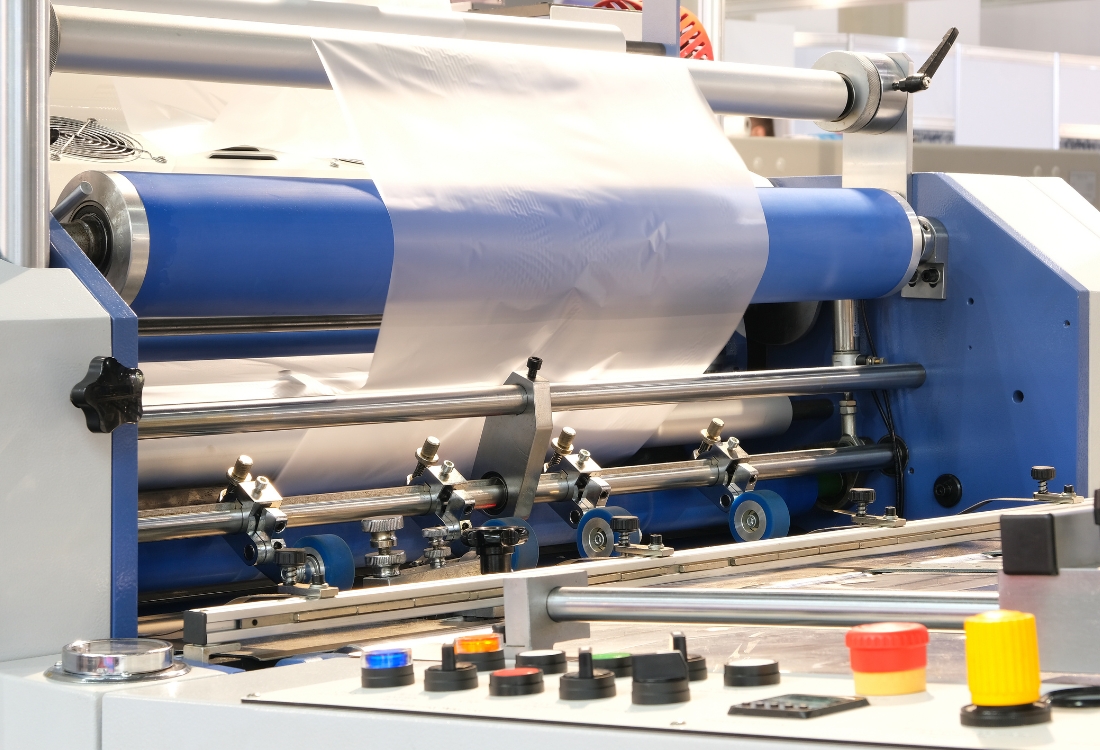

Premium doypacks engineered for shelf impact and dependable sealing—custom sizes, barrier structures, and finishes tailored to your product, filling method, and shelf-life targets. Choose from matte or gloss, clear windows, and high-definition printing, plus functional add-ons like zippers, tear notches, hang holes, and spouts. From sampling and brand launches to scaled production, we build stand-up pouches that run smoothly on real packaging lines and present beautifully at retail.

Why Choose PaperMyna Doypacks

Purpose-built for dependable sealing and shelf impact. We match size, structure, and features to your product and filling method—so your pouches perform consistently from sampling to scaled production.

Engineered for Reliable Sealing

Stable seal strength and film performance for smoother runs, fewer leaks, and fewer rejects.

Barrier Built for Shelf Life

Choose the right moisture/oxygen/light protection to keep products fresh longer and reduce returns.

High-Definition Printing

Crisp details and strong color control with premium finishes that elevate shelf presence.

Retail-Ready Features

Zippers, tear notches, hang holes, windows, valves, and spouts—built to fit how customers use and buy.

Blank Label Manufacturer

Custom Solutions for Your Brand

Stand-Up Pouch is a flexible bag with a special gusseted bottom that allows it to stand upright on its own. Made from protective multi-layer films, it offers great shelf visibility, consumer convenience(often with resealable zippers or spouts), product freshness, and is lightweight and space-efficient. Widely used for food, pet food, coffee, household products, and more.

Key Applications of Blank Labels

Key Features and Advantages:

1. Self-Supporting/Gusseted Bottom: The defining feature. The bottom has folds (gussets) that expand when filled, creating a stable base.

2. Excellent Shelf Presence: Stands upright, maximizing product visibility and brand impact on retail shelves. The large printable surface area acts as a mini billboard.

3. Consumer Convenience: Easy to store, pour from (often with resealable zippers or spouts), handle, and use. Resealable features extend product freshness.

4. Material Efficiency & Lightweight: Uses significantly less material than rigid containers (like bottles or boxes), reducing shipping weight, costs, and environmental footprint.

5. Product Protection: Typically made from high-barrier multi-layer laminated films (e.g., PET, AL foil, PE, OPP, metallized films). This provides excellent protection against:

- Moisture & Oxygen: Crucial for freshness and shelf life (food, coffee, pet food).

- Light: Protects light-sensitive products (like some vitamins or oils).

- Contaminants: Seals out dust and germs.

Premium Packaging, Engineered for Your Success

Why Choose Our Stand-Up Pouches?

Welcome to [papermyna]

Unmatched Barrier Protection Technology

-Advanced Material Science: Our pouches use proprietary 3-8 layer laminates (e.g., PET/AL/PE, metallized films) with oxygen transmission rates (OTR) <0.05 cc/m²/day and moisture vapor transmission rates (MVTR) <0.02 g/m²/day ensuring maximum freshness for sensitive products. Customized Protection: Tailored barriers for UV resistance, aroma retention, or grease resistance.

Brand-Differentiating Design & Print Quality

High-Definition Flexo/Gravure Printing: 10-color printing capability with <0.1mm registration accuracy for photorealistic graphics. Structural Innovation: Unique shapes (curved panels, asymmetrical bases), transparent windows, tactile finishes (soft-touch, embossing).

Sustainability Without Compromise

Eco-Material Portfolio: Certified recyclable mono-materials (PE/PP), 30-70% PCR content, compostable options .Lightweighting: Up to 40% less plastic vs. rigid containers – reducing carbon footprint & shipping costs.

Supply Chain Reliability

Global Compliance: Meets FDA, EU 10/2011, BRCGS standards for food/pharma safety. Agile Production: MOQs from 50,000 units, 15-day lead times for urgent projects.

Frequently Asked Questions

Answers to your most common questions provided by the label experts on our Customer Service team!

Custom roll labels and sticker rolls have a minimum order quantity of 50.

Custom die cut stickers and sticker sheets have a minimum order quantity of 25.

Keg Collars have a minimum order quantity of 1.

Yes, we offer fully customizable label solutions, allowing you to create labels in virtually any shape to meet your specific needs. Whether you require standard shapes (circles, rectangles, ovals) or unique die-cut designs, our team can accommodate your requirements. Simply provide your design specifications or logo, and we’ll handle the rest!

No, we cannot print with white ink on a printed sheet order. However, we may be able to achieve a similar look by leaving any white areas of your artwork unprinted if your printed sheet labels utilize a white material.

If white ink is essential to your label design, our custom printed roll labels and custom stickers are a great alternative option.

Our roll label materials are the most durable labels we offer, specifically any of our BOPP options. That’s because these are laminated after printing, therefore protecting your print from any harsh or weathering elements.

If you’re looking for an option on sheets, our white polyester weatherproof material is the way to go. This material is compatible with laser printers and has its own weatherproof, high heat-resistance, and tear-resistant properties. Keep in mind though that label sheets are not laminated, therefore your prints may be more likely to breakdown when exposed to any weathering elements.

Thermal Transfer Printing: Uses a heated print head to melt ink from a ribbon onto the label, creating durable, long-lasting prints. Ideal for labels exposed to heat, moisture, or chemicals (e.g., industrial or logistics labels).

Direct Thermal Printing: Applies heat directly to heat-sensitive label material, darkening it without ink or ribbon. Cost-effective but less durable; suited for short-term use (e.g., shipping labels or receipts).

Our products are shipped from our manufacturing facility located at No. 173, Beiwang Road, Zhongtang Town, Dongguan City, Guangdong Province, China.

e offer multiple shipping options to meet different needs:Express shipping:DHL, UPS, FedEx, TNT, and EMS

Sea freight:Available through our freight forwarding partners

Estimated Delivery Times:

Express Shipping:

North America/Europe: 3-7 business days

Asia/Australia: 2-5 business days

Other regions: 5-10 business days

Sea Freight:

North America: 25-35 days

Europe: 30-40 days

Australia: 20-30 days

How we help small businesses.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.