Flexible Packaging, Self-Adhesive Labels

Custom Food Packaging and Labels Manufacturer

One-stop solutions for flexible packaging and food-grade self-adhesive labels—designed for freshness, branding consistency, and efficient production.

Flexible MOQ

High-Barrier Structures

Food-Grade Materials

Factory Direct

Fast Sampling

Export Ready

What We Offer in Food Packaging Solutions

Integrated solutions covering both flexible packaging and food-grade self-adhesive labels.

Flexible Packaging

- Stand-Up Pouches

- Flat & Sachet Packaging

- Rollstock Film for FFS

- Vacuum & Frozen Packaging

- Zippers, Valves & Custom Features

Food-Grade Self-Adhesive Labels

- Product & Branding Labels

- Nutrition & Compliance Labels

- Freezer & Cold-Chain Labels

- Barcode, QR & Variable Data

- Rolls or Fan-Fold Formats

Applications We Serve

Packaging and labels built for real food workflows—ambient, refrigerated, and frozen.

Snacks & Confectionery

Coffee & Tea

Frozen Food

Meat & Seafood

Spices & Seasonings

Bakery Products

Dairy & Powder

Pet Food

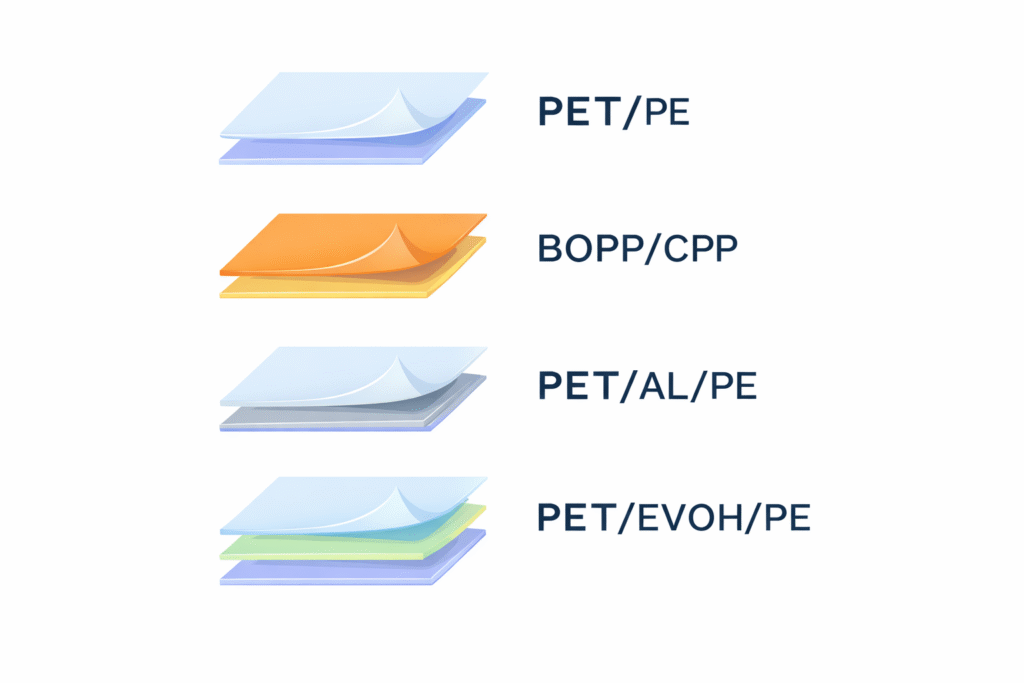

Food-Grade Materials & Barrier Structures

We recommend packaging structures based on product sensitivity, shelf-life targets, and filling conditions.

Material Options

- PET / BOPP / CPP / PE

- Aluminum Foil & Metallized Films

- EVOH High-Barrier Structures

- Reliable Heat Sealing & Seal Strength

- Cold-Chain & Freezer-Grade Options

- Matte / Gloss / Soft-Touch Finishes

- Digital & Gravure Printing Support

Not sure which structure fits your product? Send your application details and we’ll recommend the best option.

Everyday Dry Foods

PET/PE or BOPP/CPP

Balanced cost, good moisture barrier, and reliable sealing for snacks and bakery.

Aroma & Light Sensitive

PET/AL/PE (Foil Laminations)

Excellent oxygen and light barrier for coffee, nuts, and flavor-sensitive products.

Frozen & Vacuum Applications

PET/PE (Low-Temp Grade)

Cold resistance and strong seal integrity for frozen foods and vacuum packaging.

Packaging Formats for Food Products

Choose Your Packaging Format

Stand Up Pouch

Retail-ready, zipper/window options.

Flat Bottom Pouch

Premium shelf presence for dry foods.

Lay Flat Pouch

Frozen, vacuum, and portion packs.

Rollstock Film

Built for FFS high-volume lines.

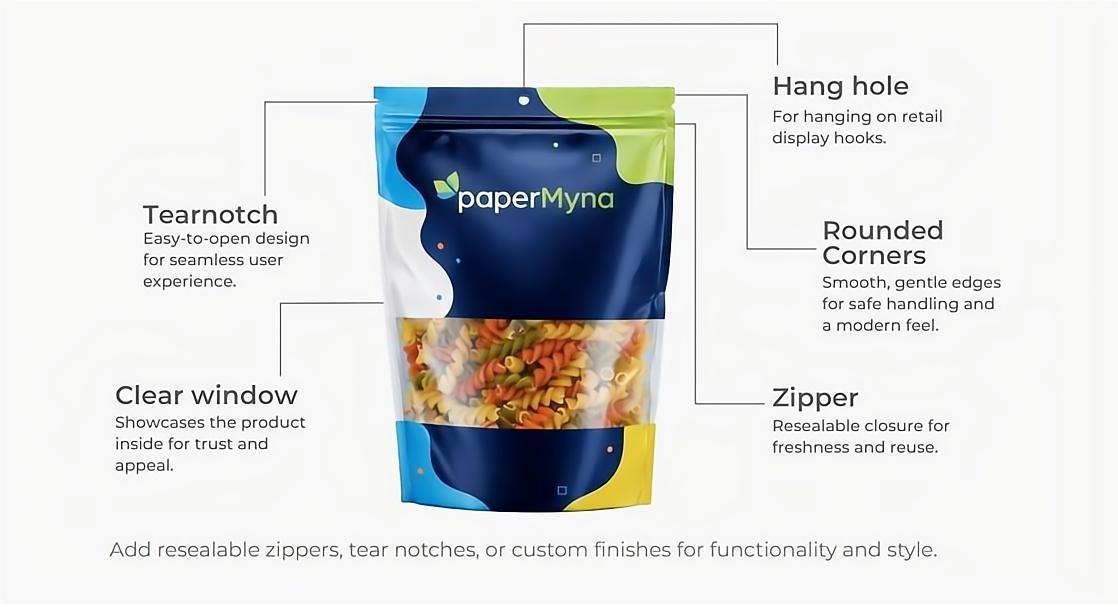

Functional Features for Custom Food Packaging

Custom food packaging is more than appearance.

We offer a range of functional features—such as resealable zippers, tear notches, hang holes, and clear windows—to improve usability, shelf performance, and consumer experience across different food applications.

Factory-Direct Food Packaging Manufacturing

Clean production, controlled processes, and reliable food-grade quality.

Why Choose PaperMyna

More than a packaging supplier — we work as your long-term manufacturing partner.

Direct Communication, Fewer Middle Steps

You work directly with the factory team for faster feedback and clearer execution.

Built for Brands That Scale

From small trial orders to volume production, our processes support long-term growth.

Application-Driven Decisions

We recommend materials and structures based on real food applications, not generic specifications.

Production-First Thinking

Packaging is designed to run smoothly on production lines with reliable sealing and cost efficiency.

Trusted by Food Brands Worldwide

Food brands choose PaperMyna for consistent quality, reliable materials, and packaging solutions built for real production and retail environments.

From structure selection to print consistency, our packaging supports long-term brand growth across domestic and export markets.

Food Brand Customer

Retail & Export Market

Frequently Asked Questions

Our MOQ depends on the packaging format, size, and material structure. For most custom flexible packaging, the minimum order quantity is set to ensure stable production quality and cost efficiency. Please contact us with your specific requirements for an accurate recommendation.

Yes. We recommend materials and barrier structures based on your product type, shelf-life requirements, storage conditions, and distribution environment. All recommendations are application-driven, not generic.

Yes. We offer sampling options depending on the project, including material samples and production samples when applicable. Sampling allows you to confirm structure, size, and functionality before mass production.

Typically, we need packaging size, material or structure preference, estimated order quantity, artwork status, and intended application. If any details are unclear, our team will guide you through the process.

Lead times vary depending on packaging type and order complexity. Sampling usually takes several days, while production timelines are confirmed after final specifications and artwork approval.

Yes. We provide both custom food packaging and food-grade self-adhesive labels, allowing consistent design, color control, and material coordination from a single supplier.